1000 Bottles Per Hour Pet Blow Molding Machine

Basic Info

Model No.: HG-2L

Product Description

Model NO.: HG-2L Raw Material: PET Automation: Non-Automatic Certification: CE, SGS, ISO9001:2008 Machine Capacity: 800-1000PCS/Hour Trademark: Hautek Type: Stretch Blow molding machine Making Method of Parison: Stretch Blow Computerized: Non-Computerized Working Power: 380V, 3 Phase, 50Hz Bottle Material: Pet Origin: China Some projects abroad of Hautek:

2001 Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant.

2003 Sri Lanka: 3,000BPH carbonated beverage production line.

2003 Maldives: 3,000BPH water bottling line (with seawater desalination)

2005 Sri Lanka: 12,000BPH carbonated beverage production line.

2006 Nigeria: 9,000BPH water bottling production line.

2006 Libya: 2,000BPH water bottling production line.

2007 Angola: 9,000BPH water bottling production line.

2008 Russia: 12,000BPH x 2 water bottling plant.

2009 Rwanda: 3,000BPH water bottling production line.

2010 Yemen: 9,000BPH water bottling plant.

2011 Cameroun: 2,000BPH water bottling production line.

2012 Nigeria: 12,000BPH water bottling plant.

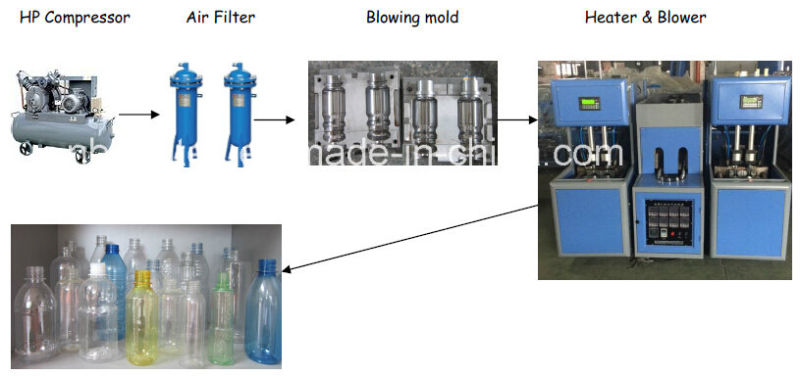

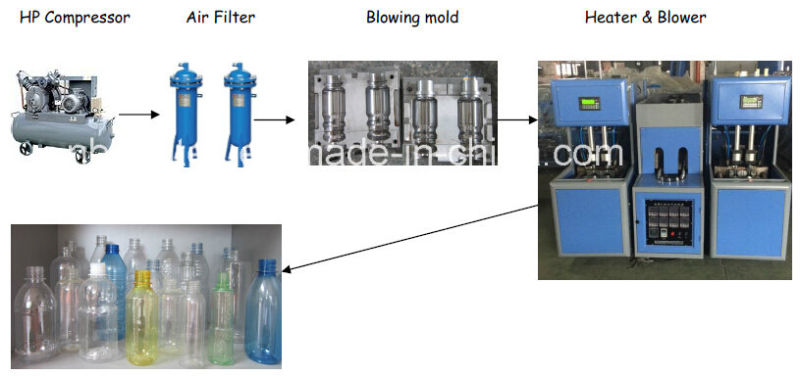

2013 Tanzania: 2,000BPH water bottling plant. Semi-Auto Bottle Blow Moulding Machine : Outstanding pneumatic system design and buffering device makes the Blow Molding Machine running smoothly with low noise. High quality pneumatic and electric components enhance machine's reliability and low maintenance. Front open clamping is good for easy operating and mold changin Infrared preheater equipped with frequency converter for higher accuracy heat distribution for the preforms. Pre-blowing helps to have better PET bottle blowing formation. With low cost and flexibility, this machine is extremely ideal for special bottle makers to have variety bottles and jars.

Blowing machine parameters :

Contact us if you need more details on Semi-Automatic Bottle Blow Molding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Semi-Automatic Blow Moulding Machine、Pet Blow Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

2001 Nigeria: 200BPH 5Gallon water bottling and 3,000BPH water bottling plant.

2003 Sri Lanka: 3,000BPH carbonated beverage production line.

2003 Maldives: 3,000BPH water bottling line (with seawater desalination)

2005 Sri Lanka: 12,000BPH carbonated beverage production line.

2006 Nigeria: 9,000BPH water bottling production line.

2006 Libya: 2,000BPH water bottling production line.

2007 Angola: 9,000BPH water bottling production line.

2008 Russia: 12,000BPH x 2 water bottling plant.

2009 Rwanda: 3,000BPH water bottling production line.

2010 Yemen: 9,000BPH water bottling plant.

2011 Cameroun: 2,000BPH water bottling production line.

2012 Nigeria: 12,000BPH water bottling plant.

2013 Tanzania: 2,000BPH water bottling plant. Semi-Auto Bottle Blow Moulding Machine : Outstanding pneumatic system design and buffering device makes the Blow Molding Machine running smoothly with low noise. High quality pneumatic and electric components enhance machine's reliability and low maintenance. Front open clamping is good for easy operating and mold changin Infrared preheater equipped with frequency converter for higher accuracy heat distribution for the preforms. Pre-blowing helps to have better PET bottle blowing formation. With low cost and flexibility, this machine is extremely ideal for special bottle makers to have variety bottles and jars.

Blowing machine parameters :

| Unit | HG-2L | ||

| Modeling | Clamping Force | kn | 120 |

| Clamping Stroke | mm | 165 | |

| Streching Stroke | mm | 370 | |

| Number of Cavities | ltr | 2 | |

| Bottle | Max. Bottle Volume | L | 2 |

| Neck Diameter Range | mm | 15-100mm | |

| Max. Bottle Diameter | mm | 20-100mm | |

| Max. Bottle Height | mm | 50-350mm | |

| Theoretical Output | bph | 1000 | |

| Electrical System | Total Power | kw | 9 |

| Heating Power | kw | 11 | |

| Max. Heating Power | kw | 16 | |

| Air System | Operating Pressure | kg/cm3 | 8 |

| Low Pressure Air Consuming | ltr/min | 400 | |

| Blowing Pressure | kg/cm3 | 15-30 | |

| High Pressure Air Consuming | kca/hr | 1000 | |

| Chilled Water | Operating Pressure | kg/cm3 | 5-6 |

| Temperature Range | ºC | 10-12 | |

| Consuming | Kcal/hr | 1200 | |

| Flow Rate | ltr/min | 25 | |

| Cooling Water | Operating Pressure | kg/cm3 | 5-6 |

| Temperature | ºC | 10-12 | |

| Consuming | Kcal/hr | 10000 | |

| Flow Rate | ltr/min | 100 | |

| Machine | Blower Size ( L x W x H ) | mm | 1550 x 610 x 1600 |

| Heater Size ( L x W x H ) | mm | 1360 x 610 x 1280 | |

| Blower Weight | kg | 650 | |

| Heater Weight | kg | 350 |

Contact us if you need more details on Semi-Automatic Bottle Blow Molding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Semi-Automatic Blow Moulding Machine、Pet Blow Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Blow Molding Machine

Premium Related Products

Other Products

Hot Products

PP Plastic Bottles Injection Blow Molding MachineAutomatic PE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding Machine32-Cavity 28mm Pco Bpf Plastic Cap Injection Mold1cbm/30kgs Air Dryer with CTA Three Grades Air FiltersABS Home Appliance Plastic Injection Mould2-Cavity 1000ml S136 Extrusion Blow Mold12-Cavity 48g 28pco Self-Lock Pet Preform Injection Mould12L Extrusion Blow Molding Machine Hst-12LWide Mouth Jar Pet Semi-Auto Blow Molding Machine Hb-M400228tons PVC Injection Molding Machine Hi-G228PVCServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P26896t Plastic Injection Moulding Machine Hi-G96