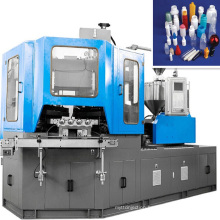

Pet Preform Specialized Injection Molding Machine

Basic Info

Model No.: KSML170

Product Description

Model NO.: KSML170 Structure: Vertical and Horizontal Composite Plasticizing Way: Screw Type Automation: Automatic Certification: CE, ISO9001:2008 Clamping Force: 1700kn Type: Preform Injection Plastic Type: Thermoplastic Clamping Way: Hydraulic & Mechanical Computerized: Computerized Injection Weight: 357g Open Stroke: 435mm

1. Stable Injection Device

A PID temperature control, precise temperature control of barrel.

There are three or four screws and barrels with optimal design

Respectively, nitride, hard plating, dual-metal, which is suitable for different processes of a variety of plastics and the choice of product.

Two-guided direct line guided bar supports, double-balanced rapid injection.

The high-torque hydraulic motors offer a stable plasticizing capacity, high-precision electronic device position detection enable accurate measurement.

Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, anti-drooling and automated auto purge,

Expected to prevent cold-start function to ensure that the screw, barrel will not be harmed.

2. Stable And Reliable Clamping Unit

Five-point double toggle diagonal structure, template design by computer optimization.

Mechanism, electronic & hydraulic triple interlock safety protection function.

Sensitive low-voltage mold protection device.

Multiple hydraulic liftout type

Multiple stages control for mold opening clamping pressure, speed positioning control

Hydraulic motor-driving gear mold adjustment.

Special technique treatment, reliable strength

Automatic centralized lubrication system

Mold open and clamping, liftout position control

Automatic mould adjustment function

Robotic pincher mechanical installation positioning interface.

Core pulling and inserting system is suitable for the complicate structure mould.

3. Fast Response, Stable Output

The manual plug value hydraulic system make the machine having quick and smooth motion response

Pressure and flow double proportional value control

Hydraulic oil cooling device

High-performance imported hydraulic unit with optimizing allocation

The fuel tank has a big opening hole so can be cleaned easily.

4. Quick Reaction Stability System

Special control the computer for Plastic Injection Machine use, control and display relatively independent with high reliability.

Technical parameters pre-setting and storage function

Parameters information protection function

Charging barrel temperature deviation automatic adjustment function

Abnormal alarm function

Front and back door emergency stop button

Real-time monitoring can display the condition of each motion

Electrical motor safety protection device

Robotic pincher interface

Cutting photoelectric switch

System hardware I/O detection function

Charging barrel temperature is controlled accurately by computer setting and PID closed-loop manner.

Screen protection function , prolong the life of screen using.

Full-enclosed electrical-controlled box, electrical components are neatly arranged, never interfere with each other.

Contact us if you need more details on 20L Pet Preform Production Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pet Preform Injection Moulding Machine、Full-Auto Injection Molding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1. Stable Injection Device

A PID temperature control, precise temperature control of barrel.

There are three or four screws and barrels with optimal design

Respectively, nitride, hard plating, dual-metal, which is suitable for different processes of a variety of plastics and the choice of product.

Two-guided direct line guided bar supports, double-balanced rapid injection.

The high-torque hydraulic motors offer a stable plasticizing capacity, high-precision electronic device position detection enable accurate measurement.

Multi-injection speed and pressure and multi-level holding pressure settings, switch from the injection time, location, pressure control to ensure the quality of molding.

Multi-level back-pressure of pre-plastic and pre-speed are computer-controlled, anti-drooling and automated auto purge,

Expected to prevent cold-start function to ensure that the screw, barrel will not be harmed.

2. Stable And Reliable Clamping Unit

Five-point double toggle diagonal structure, template design by computer optimization.

Mechanism, electronic & hydraulic triple interlock safety protection function.

Sensitive low-voltage mold protection device.

Multiple hydraulic liftout type

Multiple stages control for mold opening clamping pressure, speed positioning control

Hydraulic motor-driving gear mold adjustment.

Special technique treatment, reliable strength

Automatic centralized lubrication system

Mold open and clamping, liftout position control

Automatic mould adjustment function

Robotic pincher mechanical installation positioning interface.

Core pulling and inserting system is suitable for the complicate structure mould.

3. Fast Response, Stable Output

The manual plug value hydraulic system make the machine having quick and smooth motion response

Pressure and flow double proportional value control

Hydraulic oil cooling device

High-performance imported hydraulic unit with optimizing allocation

The fuel tank has a big opening hole so can be cleaned easily.

4. Quick Reaction Stability System

Special control the computer for Plastic Injection Machine use, control and display relatively independent with high reliability.

Technical parameters pre-setting and storage function

Parameters information protection function

Charging barrel temperature deviation automatic adjustment function

Abnormal alarm function

Front and back door emergency stop button

Real-time monitoring can display the condition of each motion

Electrical motor safety protection device

Robotic pincher interface

Cutting photoelectric switch

System hardware I/O detection function

Charging barrel temperature is controlled accurately by computer setting and PID closed-loop manner.

Screen protection function , prolong the life of screen using.

Full-enclosed electrical-controlled box, electrical components are neatly arranged, never interfere with each other.

| tandard Features | ||||

| Double-cylinder balance injection system | ||||

| Multi-stage pressure&speed injection | ||||

| Back pressure adjustment device | ||||

| Low pressure mold protevtion | ||||

| Multipe hydraulic ejector knock-out | ||||

| Mechanical electrical safety device | ||||

| Auto lubrication system | ||||

| Hydraulic pressure full proportional control | ||||

| Computer control system | ||||

| Molding data memory system | ||||

| Oil temperature controller | ||||

| Hopper magner | ||||

| Optional Features | ||||

| Double hydraulic pulling and inserting | ||||

| Air blowDV | ||||

| Hydraulic unscrew device | ||||

| Hydraulic safety device | ||||

| High speed clamping | ||||

| Linear guide | ||||

| Standard Accessory | ||||

| Anti-vibrating pad | ||||

| Spare parts kit | ||||

| Tool box | ||||

| Iubrication oil | ||||

| Optional Accessory | ||||

| Robotic pincher | ||||

| Hopper dryer | ||||

| Auto loader | ||||

| Mold clamps | ||||

| Water chiller | ||||

| Plastic dehumidizer | ||||

| Mold temperature controller | ||||

| Oilbypass filter | ||||

| Plastic granulator | ||||

| Plastic color-mixer | ||||

| Inverter |

| Machine model | KSML170 | |||

| Specification | A | B | C | |

| INJECTION UNIT | Unit | |||

| Screw diameter | mm | 42 | 45 | 50 |

| Screw L/D ratio | L/D | 23.6 | 22 | 19.8 |

| Shot volume(therretical) | cm3 | 311 | 357 | 441 |

| Injection weight(ps) | g | 283 | 325 | 402 |

| Injection rate | g/s | 138 | 160 | 196 |

| Injection pressure | MPa | 203 | 177 | 143 |

| Screw speed | rpm | 180 | ||

| CLAMPING UNIT | ||||

| Clamping force | KN | 1700 | ||

| Open stroke | mm | 435 | ||

| Space between tie bars(W×H) | mm | 470×470 | ||

| Max.Mould height | mm | 520 | ||

| Min.Mould height | mm | 180 | ||

| Ejector stroke | mm | 140 | ||

| Ejector force | KN | 50 | ||

| Others | ||||

| Max.pump pressure | MPa | 16 | ||

| Pump motor power | KW | 18.5 | ||

| Heating power | KW | 12.5 | ||

| Numbers of heating area | segment | 3+1 | ||

| Machine dimension(L×W×H) | m | 5.1×1.5×2.2 | ||

| Oiltank cubage | L | 260 | ||

| Machine weight | t | 6 | ||

| Standard Features | ||||

| Double-cylinder balance injection system | ||||

| Multi-stage pressure&speed injection | ||||

| Back pressure adjustment device | ||||

| Low pressure mold protevtion | ||||

| Multipe hydraulic ejector knock-out | ||||

| Mechanical electrical safety device | ||||

| Auto lubrication system | ||||

| Hydraulic pressure full proportional control | ||||

| Computer control system | ||||

| Molding data memory system | ||||

| Oil temperature controller | ||||

| Hopper magner | ||||

| Optional Features | ||||

| Double hydraulic pulling and inserting | ||||

| Air blowDV | ||||

| Hydraulic unscrew device | ||||

| Hydraulic safety device | ||||

| High speed clamping | ||||

| Linear guide | ||||

| Standard Accessory | ||||

| Anti-vibrating pad | ||||

| Spare parts kit | ||||

| Tool box | ||||

| Iubrication oil | ||||

| Optional Accessory | ||||

| Robotic pincher | ||||

| Hopper dryer | ||||

| Auto loader | ||||

| Mold clamps | ||||

| Water chiller | ||||

| Plastic dehumidizer | ||||

| Mold temperature controller | ||||

| Oilbypass filter | ||||

| Plastic granulator | ||||

| Plastic color-mixer | ||||

| Inverter |

Contact us if you need more details on 20L Pet Preform Production Injection Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pet Preform Injection Moulding Machine、Full-Auto Injection Molding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Injection Mold Machine

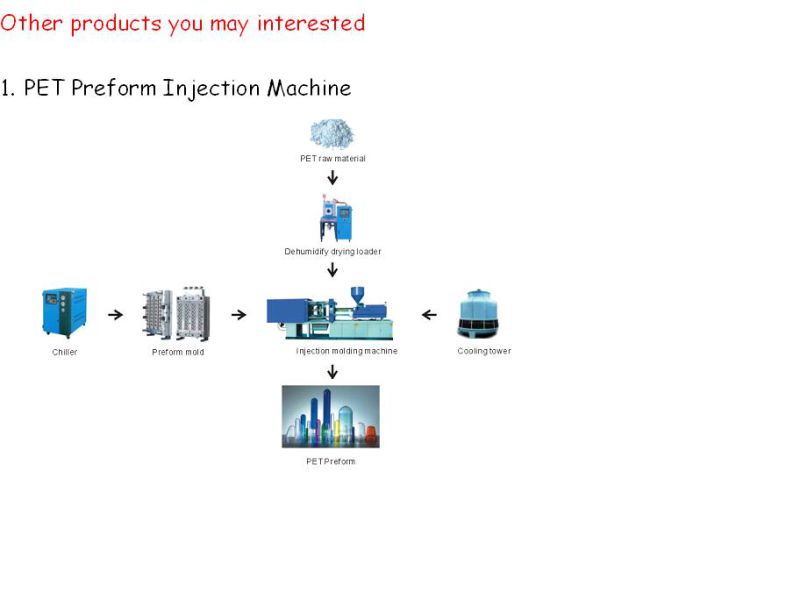

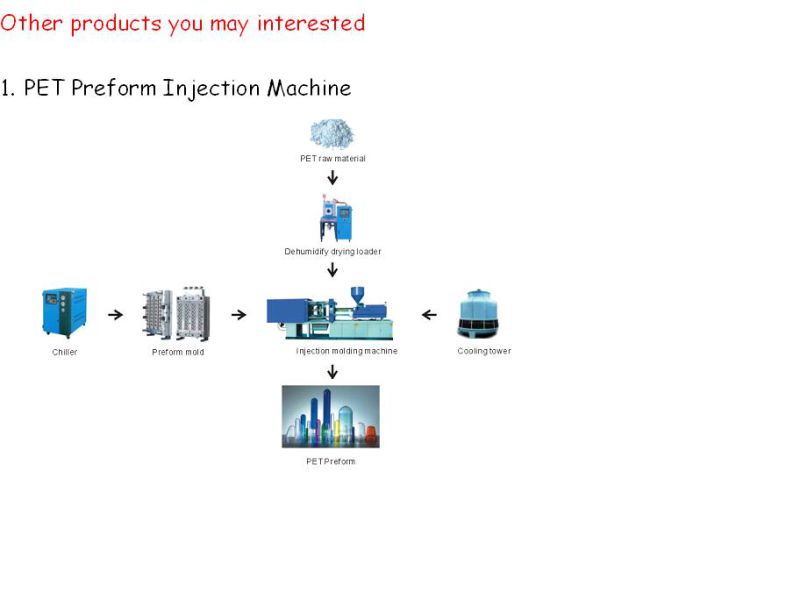

Premium Related Products

Other Products

Hot Products

PP Plastic Bottles Injection Blow Molding MachineAutomatic PE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding Machine32-Cavity 28mm Pco Bpf Plastic Cap Injection Mold1cbm/30kgs Air Dryer with CTA Three Grades Air FiltersABS Home Appliance Plastic Injection Mould2-Cavity 1000ml S136 Extrusion Blow Mold12-Cavity 48g 28pco Self-Lock Pet Preform Injection Mould12L Extrusion Blow Molding Machine Hst-12LWide Mouth Jar Pet Semi-Auto Blow Molding Machine Hb-M400228tons PVC Injection Molding Machine Hi-G228PVCServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P26896t Plastic Injection Moulding Machine Hi-G96