M-2000 Mineral Water Production Line

Basic Info

Model No.: M-2000S

Product Description

Model NO.: M-2000S Automatic Production Line: Comprehensive Flexible Production: Intelligent Manufacturing Production Scope: Product Line Machine Material: Ss304 Trademark: HAUTEK HS Code: 8421999000 Transmission Type: Flexible Automation: Automation Rhythm: Flow Production Line Machine Capacity: 2000 Bottles Per Hour Bottle Size: 0.2L ~ 2L Origin: Ningbo

With rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad.

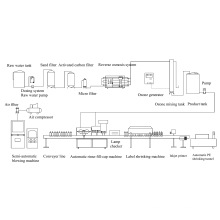

Simple water bottling line :

Suitable for customers to start bottling water business with lower investment at the beginning. With normal design, product water meets the drinking water standard quality of WHO.

The complete line including semi-automatic type Water Treatment Machine and PET bottle blowing machine, automatic bottling rinsing/filling/capping machine,semi-automatic Packing Machine etc. Customers will be easy to recover their investments in a short time and easy to increase production capacity after develop their water market.

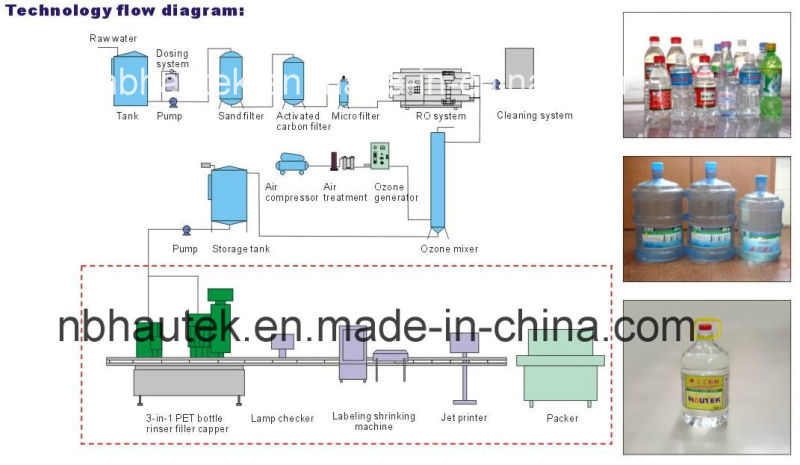

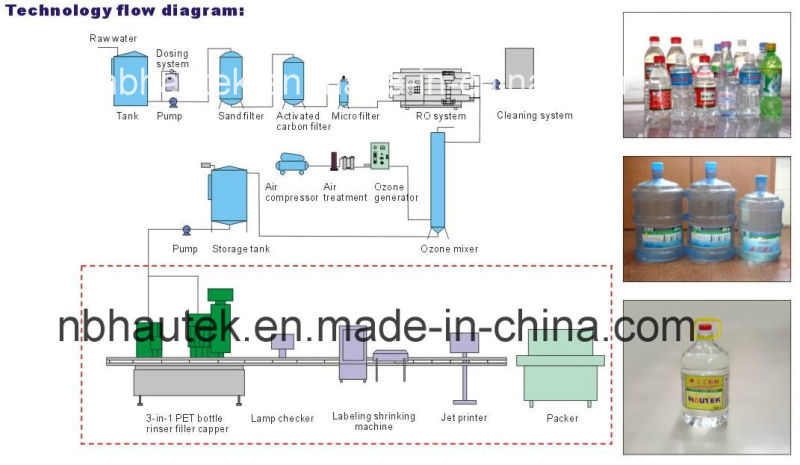

Complete mineral water plant equipment inform:

Flocculants dosing system Anti-scale dosing system

↓ ↓

Raw water→Raw water Tank→Pump1→Sand filter→Activated carbon filter→5μm micro filter→1μm micro filter→Reverse Osmosis system (with CIP cleaning system)→Ozone Generator→Ozone mixing tank→Product tank→Product pump

↓

Bottle rinsing/filling/capping machine→Lamp checker→Label inserting (by manual)→Automatic label shrinking tunnel→Ink-jet printer→Bottle loading PE film sleeve (by manual)→Automatic PE shrinking machine

1. Water feeding pump

Using branded pump to ensure the raw water flow and water pressure as required, this is first step to ensure the whole Water treatment system can run stably with the producing capacity required and quality required

2. Quartz Sand filter

Main usage: Clear the sediment, manganese, rust, colloid material, mechanical impurities, suspended solid and other particles whose volume is more than 20 UM. The effluent turbidity is less than 0.5NTU, CODMN less than 1.5mg / L, iron content of less than 0.05mg / L, SDI less than or equal to 5.

3. Active carbon filter

Usage: the active carbon filter is used for removing the pigment, smell, chemical and biological organisms, reducing the pesticide pollution and other harmful pollutants in the water.

The active carbon in the filter have strong adsorption capacity, and it can clear the organic material which is not cleared by quartz sand filter, and also will adsorb the residual chlorine in the water, and then the chlorine content in the water will be less than 0.1ML/m³, SDI less than or equal to 4, which will protect the membrane in reverse osmosis device. As we know the reverse osmosis membranes are very sensitive to chlorine.

And also the the active carbon filter can adsorb part of the metal ions in the water.

4. Micro filter

Usage: Clear the final big volume substance in water , to protect the membrane in ultrafilter.

5. RO system

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane. Reverse osmosis can remove many types of molecules and ions from solutions, and is used in both industrial processes and the production of potable water. It will final stage of water treatment process.

6.Ozone system

Usage: Disinfect RO product water and keep disinfect effect during filling process.

7. Bottle 3-in-1 rinsing/filling/capping machine

(1). Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

(2). Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

(3). The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

(4). High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

(5). Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

8. Dating machine (Inkjet printer)

Usage: To print the filling time in the bottle body or cap surface.

9. Labeling machine (shrinking tunnel)

Usage: To shrink the label on the bottle body.

10. PE film wrapping/shrinking machine

usage: To pack 6/8/12/24 bottling water in one package and material is shrinkabel PE film. Contact us if you need more details on Mineral Water Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Bottling Machine、Beverage Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

With rich knowledge of beverage project, bottling technology and bottle making machinery, HAUTEK focuses on high and middle level international market, major in beverage production line design and manufacturing, also supply relative assorted equipment. Supported by strong technical team, we offer high quality machine, good service to customers and give prompt response. We have had success in exporting and installation many beverage production lines abroad.

Simple water bottling line :

Suitable for customers to start bottling water business with lower investment at the beginning. With normal design, product water meets the drinking water standard quality of WHO.

The complete line including semi-automatic type Water Treatment Machine and PET bottle blowing machine, automatic bottling rinsing/filling/capping machine,semi-automatic Packing Machine etc. Customers will be easy to recover their investments in a short time and easy to increase production capacity after develop their water market.

| Simplified Water Bottling Line Model | Bottle | Capacity | Input water | Power spec | |

| M2000/50B/200-5L-S | M2000-S | 0.2~2.0L | 2000bph | 3000LPH | 380V, 50Hz, 3phases |

| M50B-S | 5gallon | 50bph | |||

| M200-5L-S | 5.0L | 200bph | |||

Complete mineral water plant equipment inform:

Flocculants dosing system Anti-scale dosing system

↓ ↓

Raw water→Raw water Tank→Pump1→Sand filter→Activated carbon filter→5μm micro filter→1μm micro filter→Reverse Osmosis system (with CIP cleaning system)→Ozone Generator→Ozone mixing tank→Product tank→Product pump

↓

Bottle rinsing/filling/capping machine→Lamp checker→Label inserting (by manual)→Automatic label shrinking tunnel→Ink-jet printer→Bottle loading PE film sleeve (by manual)→Automatic PE shrinking machine

1. Water feeding pump

Using branded pump to ensure the raw water flow and water pressure as required, this is first step to ensure the whole Water treatment system can run stably with the producing capacity required and quality required

2. Quartz Sand filter

Main usage: Clear the sediment, manganese, rust, colloid material, mechanical impurities, suspended solid and other particles whose volume is more than 20 UM. The effluent turbidity is less than 0.5NTU, CODMN less than 1.5mg / L, iron content of less than 0.05mg / L, SDI less than or equal to 5.

3. Active carbon filter

Usage: the active carbon filter is used for removing the pigment, smell, chemical and biological organisms, reducing the pesticide pollution and other harmful pollutants in the water.

The active carbon in the filter have strong adsorption capacity, and it can clear the organic material which is not cleared by quartz sand filter, and also will adsorb the residual chlorine in the water, and then the chlorine content in the water will be less than 0.1ML/m³, SDI less than or equal to 4, which will protect the membrane in reverse osmosis device. As we know the reverse osmosis membranes are very sensitive to chlorine.

And also the the active carbon filter can adsorb part of the metal ions in the water.

4. Micro filter

Usage: Clear the final big volume substance in water , to protect the membrane in ultrafilter.

5. RO system

Reverse osmosis (RO) is a water purification technology that uses a semipermeable membrane. Reverse osmosis can remove many types of molecules and ions from solutions, and is used in both industrial processes and the production of potable water. It will final stage of water treatment process.

6.Ozone system

Usage: Disinfect RO product water and keep disinfect effect during filling process.

7. Bottle 3-in-1 rinsing/filling/capping machine

(1). Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

(2). Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

(3). The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

(4). High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

(5). Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

8. Dating machine (Inkjet printer)

Usage: To print the filling time in the bottle body or cap surface.

9. Labeling machine (shrinking tunnel)

Usage: To shrink the label on the bottle body.

10. PE film wrapping/shrinking machine

usage: To pack 6/8/12/24 bottling water in one package and material is shrinkabel PE film. Contact us if you need more details on Mineral Water Production Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Bottling Machine、Beverage Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Water / Juice Bottling Line

Premium Related Products

Other Products

Hot Products

PP Plastic Bottles Injection Blow Molding MachineAutomatic PE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding MachineHDPE Bottles Injection Blow Moulding Machine32-Cavity 28mm Pco Bpf Plastic Cap Injection Mold1cbm/30kgs Air Dryer with CTA Three Grades Air FiltersABS Home Appliance Plastic Injection Mould2-Cavity 1000ml S136 Extrusion Blow Mold12-Cavity 48g 28pco Self-Lock Pet Preform Injection Mould12L Extrusion Blow Molding Machine Hst-12LWide Mouth Jar Pet Semi-Auto Blow Molding Machine Hb-M400228tons PVC Injection Molding Machine Hi-G228PVCServo Motor Injection Molding Machine 96t Hi-Sv96Pet Preform Injection Molding Machine 268t Hi-P26896t Plastic Injection Moulding Machine Hi-G96